PUF / PIR Slabs

SIGMA PROJECTS offers a wide range of Insulation Slabs and Pipe Sections with or without lamination for diverse applications such as:

Lamination for under-deck roof insulation, construction and insulation of pre-fabricated modular rooms for refrigerated ware housing, cold storages and reefer containers. Architectural Panelling & Partitions for offices, computer rooms and false-ceilings handling equipment in critical industries where temperature conditions play a very important role and also sound absorption sound treatment of walls and ceiling, acoustic enclosures.

In certain cases for higher temperature, special Poly-isocyanurate PIR pipe sections & slabs may be supplied on reqest which can withstand temperature of upto as high as 140 ℃.

Fixing of Slabs & Pipe sections is normally done with local adhesives or bitumen.

SIGMA PROJECTS Slabs & Pipe sections are available in standard sizes and also special sizes as per customers technical requirement.

Old techniques of wooden pipe support for the errection of plants & pipe lines is now replaced by PU pipe supports.

PUF / PIR Pipe Section / High Density Pipe Supports

A pipe support system of truly revolutionary propositions

Pipe supports are made from specially-formulated chemical systems that result in high density rigid urethane foam.

The very nature of the material immediately yields several advantages:

Property

- Wide density range possible

- Pre-engineered at our factory

- Material has a closed cell structure

- Excellent 'K' value

- Good fir resistance

- Close dimensional tolerances

- Supplied in assembled condition, complete with all metal attachments

- Special sizes, shapes and finishes on request

Advantages

- Higher densities enable higher loads without increase in surface area.

For light loads, lower densities can be used, resulting in significant savings in cost - No sawing and shaping at site. The support precisely matches your pipe's OD.

Installation time dramatically reduced. - Does not permit water penetration.

No wet rot.

No dry rot. - Provides vastly superior insulation as compared to timber and other materials.

No condensation at support point. So no drips, puddles or energy wasted. - - Improved safety at site.

Improved durability - Pipe support thickness precisely matches insulation thickness, resulting in neat finish at support location.

- Improved speed of installation.

Joint-free in the load bearing area, even for larger diameters of pipe. - Non-standard sizes and shapes can be manufactured to suit your specification.

Supports can be supplied with a factory-applied coat of fire-resistive mastic, which also serves as a vapour barrier, on the exposed surface.

This features make the pipe support system of choice for every low-temperature pipe installation - whether its a new pipe rack, or a revamp of an existing one.

PUF In-situ Jobs At Site

Like other urethane foam insulants, PUF IN-SITU has low thermal conductivity, low smoke emission and low water vapour permeability.

Unlike the others, through, PUF IN-SITU has two distinctively different features. It can be factory-moulded to any shape and, for most applications; the need for a facing material is completely eliminated. Together, these features combine to make PUF In-situ the speediest and most convenient solution to the most difficult insulation jobs.

Dramatically reduces installation time

Because its mouldable to any shape, PUF IN-SITU can be ordered prefabricated in forms that for your application precisely.

Apart from our by-now-famous slabs and pipe sections, we offer PUF In-situ in three other standard application formats:

Heavy duty pipe supports: easy to install because they are prefabricated, PUF In-situ supports eliminate the dependence on hard-to-find, hard-to-work and not-prone wood.

Foam-plus-mineral-wool 'sandwich' pipe sections: The most elegant solution for heat-traced lines in systems operating at dual temperatures.

Horton Sphere petals: A double-layer overlapping system of curved 1 m x 1 m tiles that precisely fit a Horton sphere, enabling complete reinsulation during normal maintenance shutdowns.

With these and custom formats available on order, to suit the shape and curvature of your equipment, installation becaomes a snap. All you do is apply adhesive and fit the insulation into place.

No facing material required

In flat-board applications, where facing material is normally not required, you get to specify the density you want. From the normal 36 kg/m3 that most applications require, to the 90 kgm3 used in our saddles.

And in its custom-moulded forms, like the pipe sections or Horton sphere sections, PUF In-situ comes out of the factory with its own integral, scuff and water resistant skin.

Monolithic and impervious to moisture, this skin is the natural result of our moulding process. So there's no need for extra materials or labour to add on a facing that you'd have to throw away anyway.

An insulant for all seasons

Resistant to almost all solvents, PUF In-situ is compitable with cold applied adhesives, sealants and vapour-barrier mastics.

PUF In-situ is available in boards, pip sections, radiused and bevelled lags, with or without factory-laminated facings.

PUF Spray / Polyurea Coatings

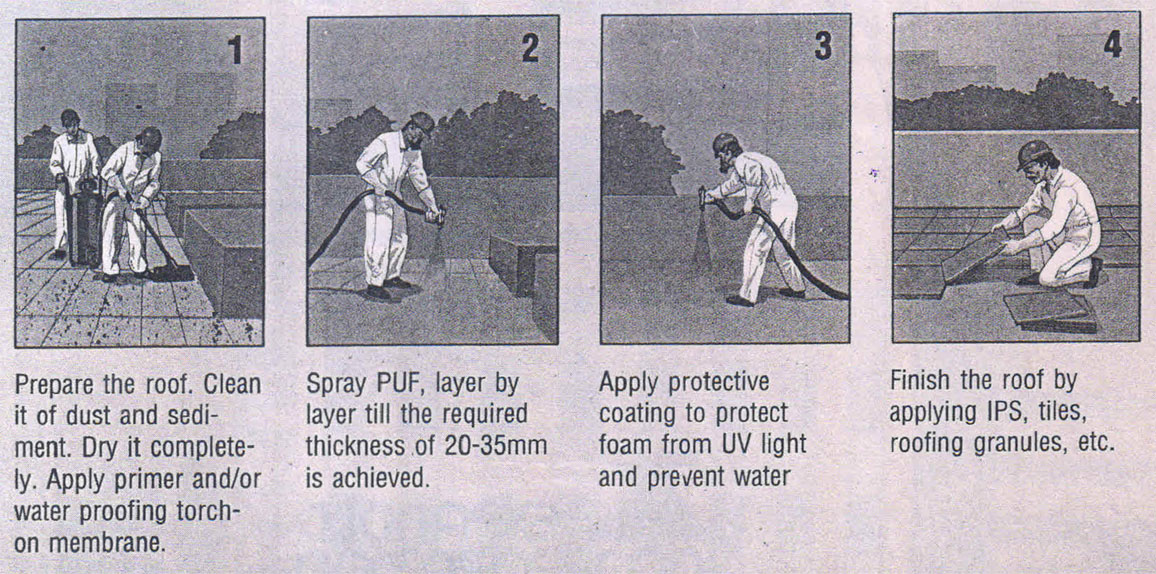

The construction industry faces two persistent problems: the energy-leaking roof and the water-leaking roof.

Given the prohibitive cost of energy today, every architect, consulting engineer and building owner realises the importance of a truly energy - efficient roof insulation system. Insulation that can effectively, and efficiently, protect the building from the assault of the elements and cut down the high cost of maintaining the ambient temperature within the building.

If the insulation system can, at the same time, prevent water seepage from the roof, its value is multiplied several times.

Our polyurethane foam covered with other protective membranes (supplied by other manufacturers) creates a unique roof system which provides a simultaneous solution to both these nagging problems.

Polyurethane Foam which is spray-applied directly onto the roof by nozzle-mixing of two seperate liquid streams comprising a polypol and an isocyanate respectively. On spraying, the mixture of these two chemicals rises to create a highly cross-linked, cellular Rigid Polyurethane possessing a closed-cell structure. The gases trapped within the unbroken walls of these cells impart excellent thermal insulation.

Why Architects Prefer PUF Roof Insulation System

Saving in energy costs

Roofing system is the most efficient insulation system providing two to three times thermal resistance of other conventional insulating materials. Compared with an equivalent thickness of insulated built-up roofing, the roof system reduces heating and air-conditioning costs by as much as 20 to 40 percent.

PUF Sandwich Panels / PUF Doors / Sheets For Fishing Boats

SIGMA PROJECTS Polyurethane insulated panels, doors and sheets offer an economical concept for the manufacture of cold-rooms, totally eliminating the usage of conventional insulation materials.

SIGMA PROJECTS sandwiched Panels comprise of a Rigid Polyurethane core composite with an average density of 42 ± 3 kg/M3 sandwiched between two flat faced or profiled metal facing in a one step manufacturing process.

SIGMA PROJECTS Sandwiched Panels are manufactured in a dedicated self-designed panel press where the Rigid Polyurethane foam react is poured in a single moulded shot with a high pressure machine.

Heavy emphasis is laid on providing the highest standards of material and workmanship with guarantee on the finished product.

SIGMA PROJECTS Panel locks are an impact resistant which gives it strength without the need for complicated ribs. There is no void formation around the lock area and results in retention of strength in the insulated panel.

SIGMA PROJECTS offer their customer custom made light-weight, impact resistance panels which are fabricated with GI, SS or as per requirement. Other fittings are manufactured from SS or Aluminium specially required for the food processing industry.

Cold Room Insulation / Insulation Of Refrigerated Vehicle

With enriched industrial experience and knowledge, we are providing a qualitative Cold Room Insulation Service and Refrigerated Vehicle.. The provided service is executed as per the requirements of our precious clients. Our company specializes in offering high grade PUF Insulated Cold Room. We offer cold room especially designed for storage of food, Phrama , Chemical, Fruits & Vegetables, Dairy , Meat items, etc. In addition to this, while carrying out the manufacturing process of these cold rooms, our professionals keep in mind the established quality standards and latest market trends. Our puf insulated cold room is available in any size since the nature of puf panel in customized. also required thickness for the required temperature. Furthermore, the offered service can be availed by our precious client's at most reasonable price.