TECHNICAL SPECIFICTIONS OF PUF

| Standard Density | 40 ± 2 Kg./m3 |

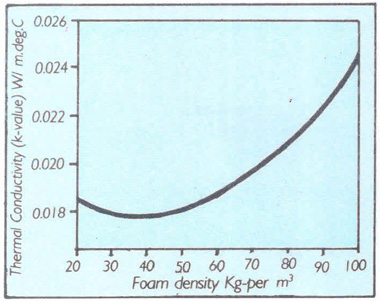

| Thermal conductivity ( K Value ) | 0.016 – 0.017 Kcal / Mhr 1˚C |

| Compressive Strength | 1.5 – 2 Kg. cm2 |

| TemperatureRange | 180˚ C to + 110˚ C |

| Closed cell contents | 1.6 – 2.0 per ms / inch |

| Dimensional Stability ( Linear Change ) | < 2% |

| Fire Resistance | Ignitability – Class ‘P’ ( not easily ignitable) ( As per BA 476 Part – 5, 1988.) Mean extend of burn-less than 125 mm. |

Thermal Conductivity or 'k' values of typical building materials. The lower the k vlaue the better the material is at resisting heat energy transfer.

| Material | k value W/m/K | Relative to foam insulation performance assuming still air and dry conditions |

| Polyurethane Foam | 0.020 | 100% |

| Mineral Wool | 0.045 | 44% |

| Timber | 0.15 | 13% |

| Plasterboard | 0.25 | 0.08% |

| Block | 0.60 | 0.03% |

| Brick | 0.80 | 0.025% |

| Mortar | 0.90 | 0.022% |

| Glass | 0.90 | 0.022% |

| Concrete | 1.0 | 0.020% |

| Steel | 36 | 0.0006% |

TECHNICAL SPECIFICTIONS OF PIR

| PROPERTIES OF PIR (Polyisocyanurate ) RIGID FOAM | ||||

| No | Property Description | Standard | Result | Test method |

| 1 | Density | >50 Kg/cu m | 52 Kg/cu m | ASTM D 1622-63 |

| 2 | Closed cell content | >95% | 96% | ASTM D 2856-70 |

| 3 | Thermal Conductivity | < 0.02 Kcal/m.h.degC at 23deg C | 0.022 Kcal/m.h.deg C | |

| 4 | Compressive strength at 10% deflection @ 20deg C | >2.5 kg/sq cm in any direction | 2.7 Kg/ sq cm | ASTM D 1621-73 |

| 5 | Surface spread of flame | class 1 | Compliant | BS 476 part 7 |

| 6 | Product ignitability | class P | Compliant | BS 476 part 5 |

| 7 | Residual weight of sample | >90% isocyanate | 92.2% isocyanante | ASTM D 3014-76 |

The organic blowing agent trapped within the closed cells of the foam, having very low thermal conductivity, makes the Rigid Polyurethane foam an exceptionally efficient insulation material for a given thickness. It provides greater resistance to the transfer of heat (or cold) than any other commercially available insulting material.